The challenge

Amsterdam-based vertical farming company GROWy wants to produce food in a future-proof and circular way. Its mission is to provide local, zero-waste, nutritious, affordable and tasteful produce.

To globally scale this innovative concept, GROWy partnered up with INFO to create the world’s first fully robotized, zero-waste vertical farm. We combined our expertise in human-centered design, robotics, IoT sensors and data science to co-create a fully automated Farming-as-a-Service (Faas) solution. FaaS is a promising business model in which GROWy builds vertical farms and manages them as a service for their customers. Together, we embarked on an extensive journey to shape the vision for FaaS and to provide actionable evidence to properly build, test and scale towards a fully automated Plant Manager.

Our solution

Service Design for a plant-centered business

We can find the challenge of this project on the intersection of plants, robots, users and, ultimately, creating a positive impact for farmers, consumers and society as a whole. To solve this complicated challenge, we used our proven Service Design approach. We helped GROWy to scope their vision and to define a strategic roadmap towards the implementation of a minimum viable product (MVP).

Gaining a deep understanding of the GROWy ecosystem

To better understand the interaction between plants, humans and robots, we conducted research to map out the essential processes involved in a plant’s lifecycle. Through in-depth sessions with stakeholders and interviews with growers, we gained a deep understanding of the GROWy ecosystem. This allowed us to define a reliable and feasible starting point, and to determine the steps needed to realize the FaaS solution, including data strategy, an implementation roadmap and a business case.

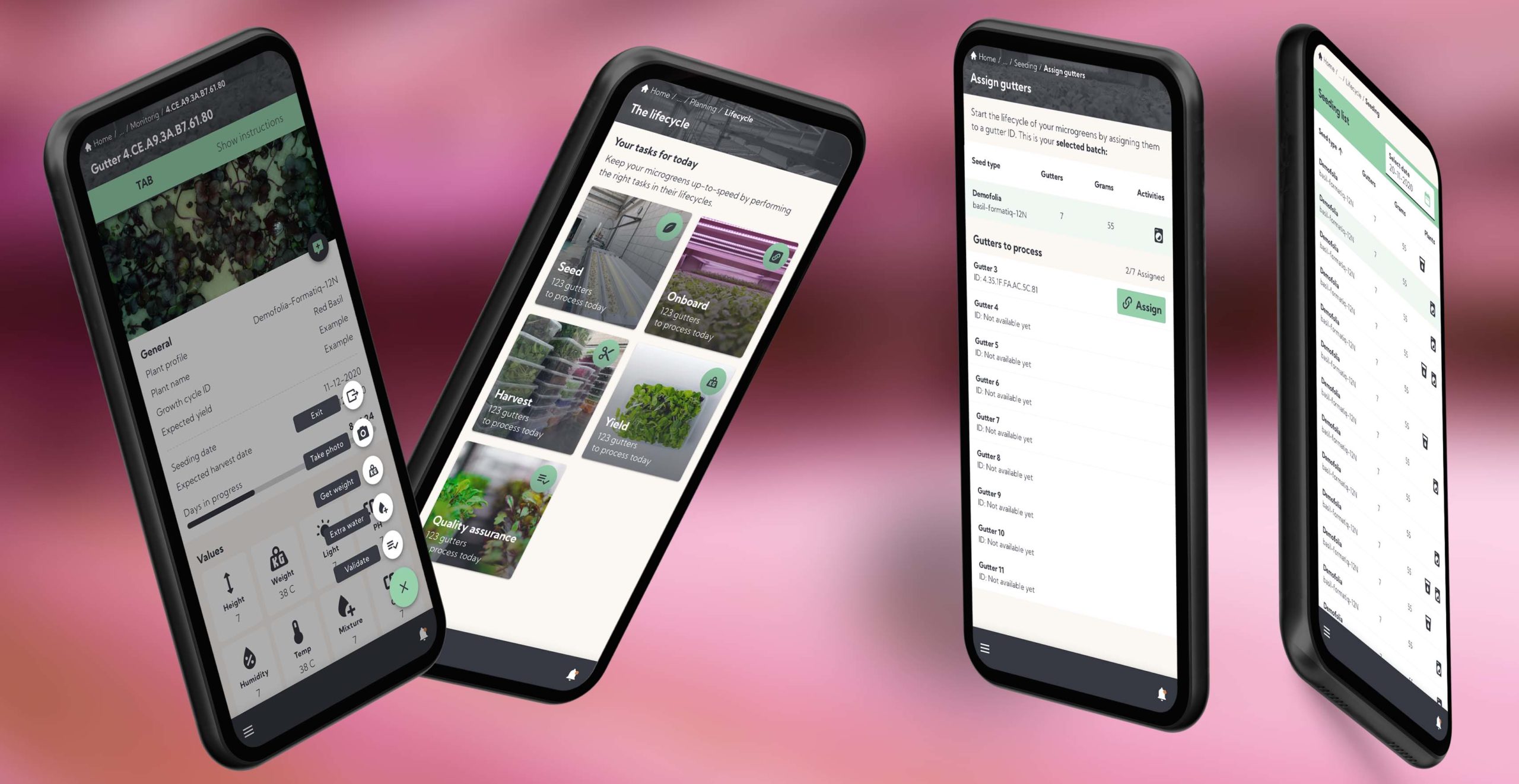

To support the planning and logistics of the seed sowing and growing of the produce, we designed the Plant Manager. The platform is powered by robotics and IoT-enabled sensors. It automates the seed sowing schedules and manages the capacity of the cells. We used advanced sensor technology and our digital twin capabilities for designing, building, monitoring and optimizing the lighting, watering and climate conditions of the vertical farm. A proper understanding of the optimal plant profile and influencing the time and yield of the produce leads to the vertical farm being operated completely automatically.

Building the Plant Manager System

Together with GROWy, we formed a multidisciplinary agile team to work towards the realization of an MVP. We used an AWS-based, serverless microservice architecture to achieve a flexible, scalable and cost-effective system.

The first version of the Plant Manager was released at the beginning of 2021. It integrates the newest possibilities of data science (AI-driven collection and analysis of optimal growth scenarios) with centrally operating the day-to-day activities of a vertical farm. Combining different technologies, this system generates, captures, analyzes and learns from the data to optimize the plant’s growth. It also manages the farm’s automation, controlling the daily operations and production planning. It allows GROWy to fully manage the farming processes and to access the data smoothly and remotely.

Together, GROWy and INFO developed a vertical farm that is fully-automated, AI-driven, almost completely circular and with a cost price that can compete with regular farms. The whole concept is simple and efficient, and focuses primarily on plant growth and market demands. This is the first step on our long-term journey and partnership to help GROWy to become the world’s most cost-effective, high-quality and sustainable autonomous vertical farm.